Case Studies

Loulo: Mali

Company: Barrick (previously Randgold),

Three advanced LRSs (which consist of a high turn down ratio LRS and a Mill Safe Start) to be installed at the one primary and the two regrind mills.

Tharisa Minerals: South Africa

Voyager Platinum Concentration Plant

This platinum concentrating plant installed Mill Safe Start Systems on two of their primary mills and one secondary mill.

Nkomati: South Africa

Company: African Rainbow minerals

Two Mill Safe Start Systems were installed at this nickel plant – one each on their Ball and Fag mills, which starts up with LRSs. The Fag mill switches over to a Slip Energy Recovery Drive after start-up.

Ngezi: Zimbabwe

Company: Zimplats

Mill Safe Start systems were installed at the two 6,5 MW ball mills at this platinum mine after periodic testing was done for a few years prior.

Tumela: South Africa

Company: Anglo American

A Mill Safe Start with a high turndown ratio LRS was installed on this 15 MW compressor that ensures that there is fresh air for the miners underground. This combination is called an Advanced LRS, manufactured to SDG specifications.

Siguiri: Guinea

Company: Anglo Gold Ashanti

A Mill Safe Start was installed for the 6MW Ball mill at this site. Start-up torque compensation and rotor protection is done by controlling the dipper speed based on the motor performance.

Lafarge: South Africa

Company: Lafarge

The KLN 4 production line at Lafarge Lichtenburg’s Raw Mill, Coal Mill and 1MW Fan were regularly breaking down and resulted in down time and production losses. Evaluation tests done on the Liquid Resistant Starters(LRS) confirmed that the starters generated high startup torque spikes

Lion: South Africa

Company: Glencore Merafe

This ferrous plant has two lines. On line one we have two LRS condition monitoring systems installed and on line two there are two air-blast coolers installed with remote temperature monitoring. These mills are batch mills and start up 4-6 times per hour.

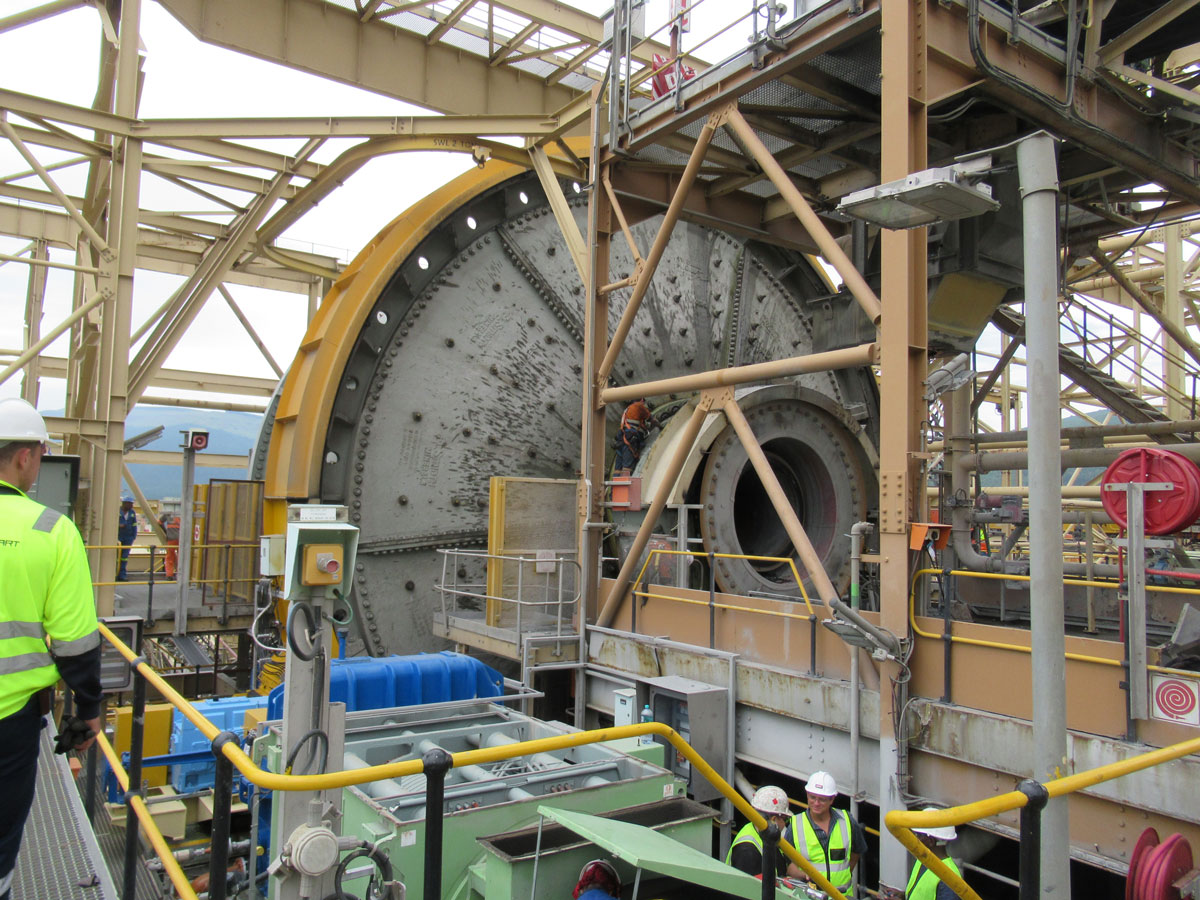

Didipio Mine: Philipinnes

Company: Oceana Gold

This gold mine installed Mill Safe Start Systems on both their Ball and Sag mills. The Sag mill switches over to a Slip Energy Recovery Drive after start-up.

Tarkwa: Ghana

Company: Goldfields

This gold mine was the first to install Mill Safe Start Systems on both their Ball mill(dual pinion 14 MW) and Sag mill. We actively monitored these mills ever since.

Constantia: Peru

Company: Hudbay

This new gold mine installed Mill Safe Start Systems on their two Ball mills (16MW dual pinion) and their two Sag mills (16MW dual pinion). These are the biggest mills where the Mill Safe Start has been installed to date.

Damang: Ghana

Company: Goldfields

This gold mine installed Mill Safe Start Systems on both their Ball and Sag mills. We actively monitored their mills ever since. A new high turndown ratio LRS was shipped to them at the end of 2019.

Constantia: South Carolina, USA

Company: Oceana Gold

Mill Safe Starts were installed for lock charge protection on both their Ball and Sag mills (rated 4000HP). These mills are started up with VSDs for which we provide lock charge protection.

Lion: South Africa

Company: Glencore Merafe

This ferrous plant has two lines. On line one we have two LRS condition monitoring systems installed and on line two there are two air-blast coolers installed with remote temperature monitoring. These mills are batch mills and start up 4-6 times per hour.

Constantia: South Carolina, USA

Company: Oceana Gold

Mill Safe Starts were installed for lock charge protection on both their Ball and Sag mills (rated 4000HP). These mills are started up with VSDs for which we provide lock charge protection.

Get In Touch

- 14 Partridge Ave, Kempton Park, 1620, South Africa

- +27 10 003 1015

- info@sdgtech.co.za

Find Us