MIll Safe Start

What is Safe Start?

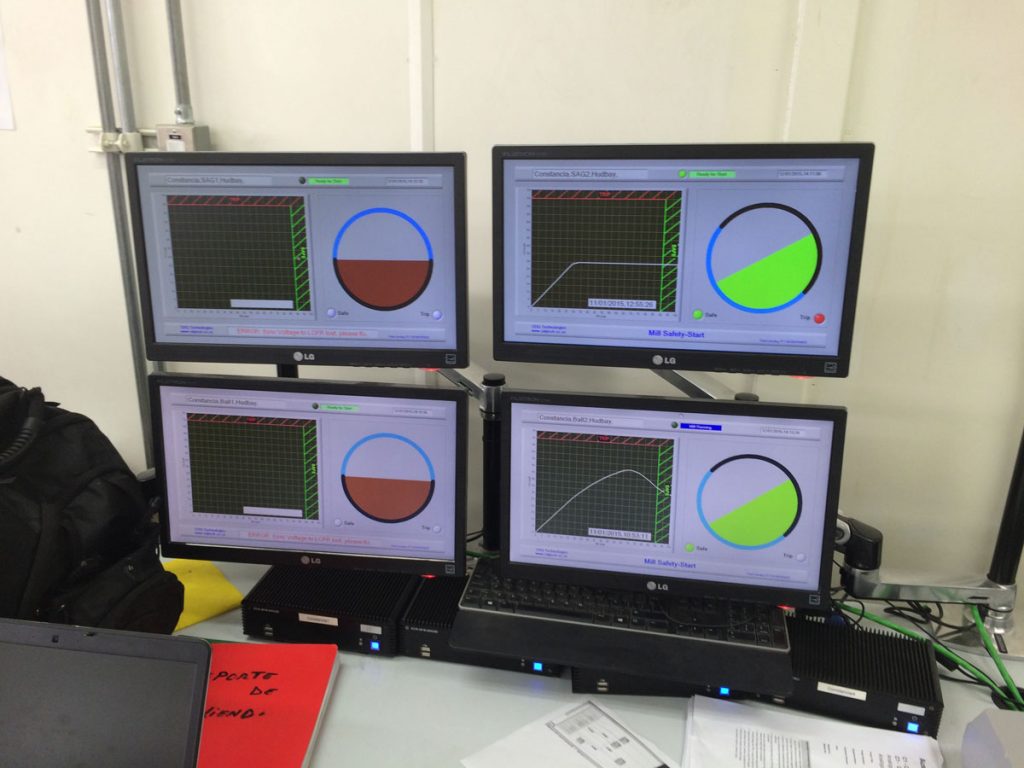

The main product of SDG Technologies is the Mill Safe Start dropped charge protection and LRS monitor which records each and every start-up and uploads it to a server, where torque traces are generated in pdf format. This report is emailed, monitored by SDG and available online. As all information is available on each start-up, this allows trending of the LRS performance and also immediate notification if something goes wrong with the LRS.

All equipment can be safely connected while the mill is running, although it is normally done once the mill has stopped. The mill is stopped under full load conditions and started again immediately. The equipment may be disconnected while the mill is running. The only production time lost is therefore a single mill stop and start, if the safety procedures on site allows.

How does it work?

To evaluate LRS performance, SDG records rotor currents and voltages during a full load start-up and evaluates the LRS using specially developed hardware and analysis software. The tests are quick, with minimal production loss.

The extent of the mechanical failures caused by bad LRS performance varies greatly depending on frequency of starting, quality of the mill manufacturing and safety factors in mill design.

The Mill Safe Start records each and every start-up and uploads it to a server, where torque traces are generated in PDF format. This report is emailed, monitored by SDG and available online. As all information is available on each start-up, this allows trending of the LRS performance and also immediate notification if something goes wrong with the LRS.

- 14 Partridge Ave, Kempton Park, 1620, South Africa

- +27 10 003 1015

- info@sdgtech.co.za