Problem

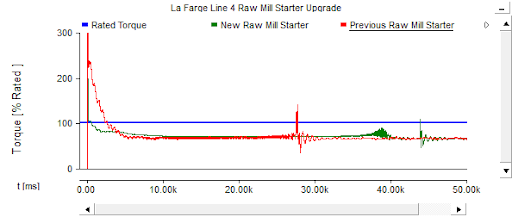

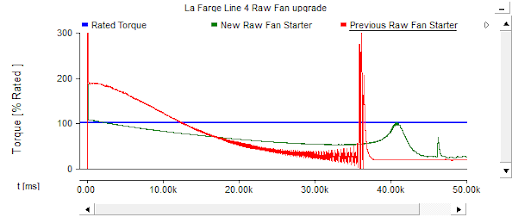

The KLN 4 production line at Lafarge Lichtenburg’s Raw Mill, Coal Mill and 1MW Fan were regularly breaking down and resulted in down time and production losses. Evaluation tests done on the Liquid Resistant Starters(LRS) confirmed that the starters generated high startup torque spikes and were subjecting the drive trains to damaging high torque spikes and transients. It was not possible to maintain the starters as no spares were available, putting maintenance and production personnel under pressure.

Intervention

SDG Technologies replaced the RAW Mill, Coal Mill, and 1MW Fan LRS Starters with new RWW LRS Starters that have high turn down ratios and acceptable starting torques and can be maintained. The new LRS Starters were also fitted with VTs, CTs and a condition monitoring interface that will allow the startup currents and voltages to be measured safely without production down time.

Project outcome

The new starters can be maintained. Spare parts, circuit diagrams and support are available.

The start-up torque spikes are within acceptable limits

The starters have sufficient turn-down ratios that ensure that the stating torque are not more than 120% of the rated torque.

Each new LRS is equipped with a condition monitoring interface that can be used to monitor the unit’s startup performance with a portable recorder.

Condition monitoring interface provides safer testing conditions.