Testing a

Liquid Resistance Starter

Would you like to test the performance of your current LRS?

- Are you experiencing any issues with your LRS?

- Are you experiencing any breakages or failures in your drivetrain?

- Are you experiencing high temperatures with your LRS system?

- Is your Mill startup torque too high?

- Does your mill trip on startup?

- Are you experiencing any gearbox or motor related failures?

- Is your LRS tuned and configured correctly?

Testing & Tuning of an LRS

Improve your LRS’ performance and save your motor/ gearbox! We provide testing of your Liquid Resistance Starter (LRS) and provide full breakdown of the testing process. Schedule a test on your LRS today!

Why do you need to test your LRS?

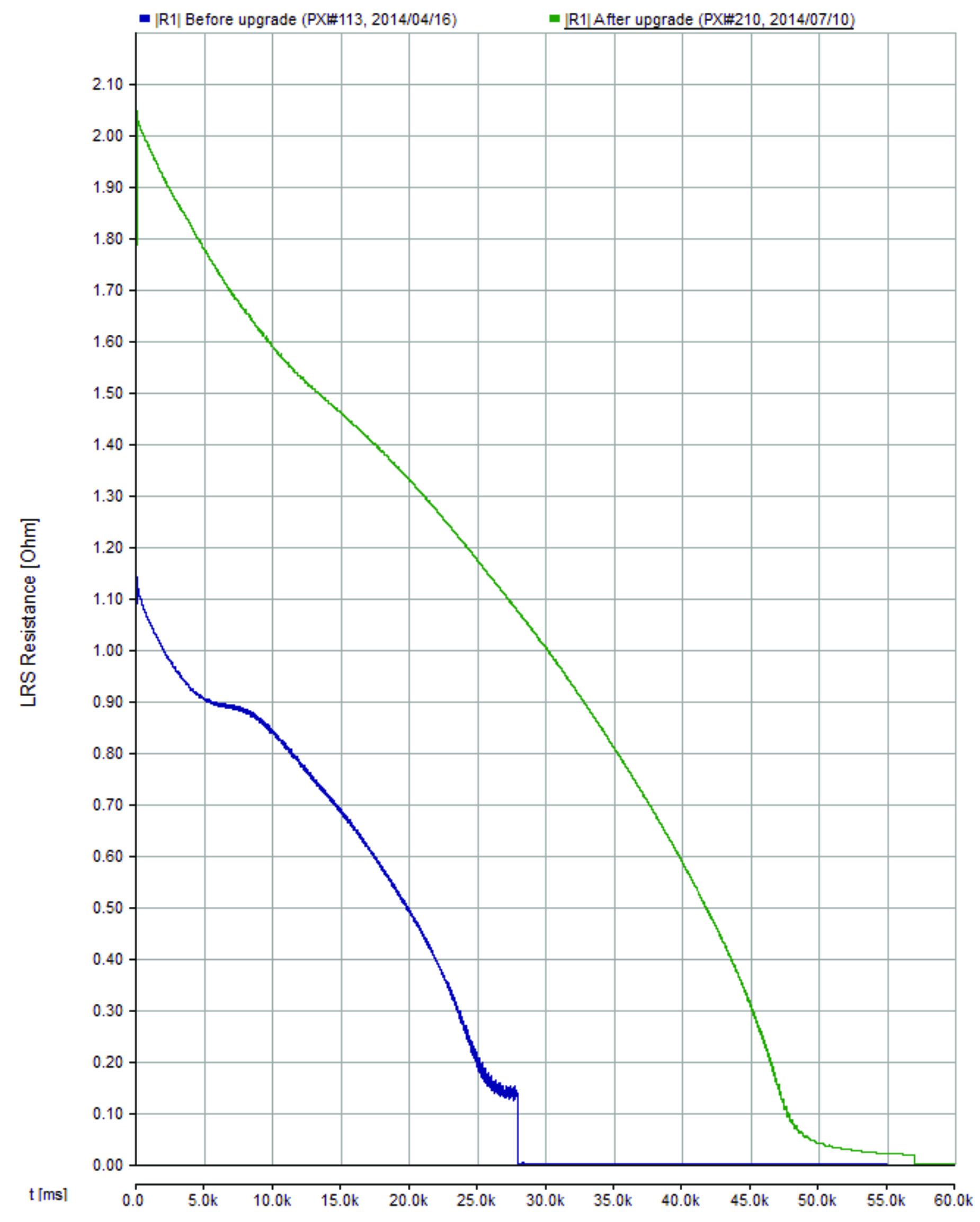

The only way to know if the LRS is performing as it should is to do a test where the rotor currents are recorded during start-up and torque traces are developed from it. Replacement of electrodes will be proposed when the Turn-Down Ratio is too low and/ or when the shorting spike is dangerously high.

Get In Touch

- 14 Partridge Ave, Kempton Park, 1620, South Africa

- +27 10 003 1015

- info@sdgtech.co.za

Find Us