Problem:

The mine’s Compressor no 8, a 15 MW compressor, was flagged as the mine’s worst performing asset. The compressor had a history of frequent breakdowns, including gearbox and motor failures, resulting in high repair and maintenance costs.

Intervention:

A new high turndown LRS with stainless electrodes and a MillSafeStart Condition Monitoring, Protection and Control system were installed and commissioned in December 2018. The dipper movement were controlled with a VSD. The new LRS electrolyte mixture was made with purified(RO) water and tuned to minimize the damaging starting torque spikes.

Result:

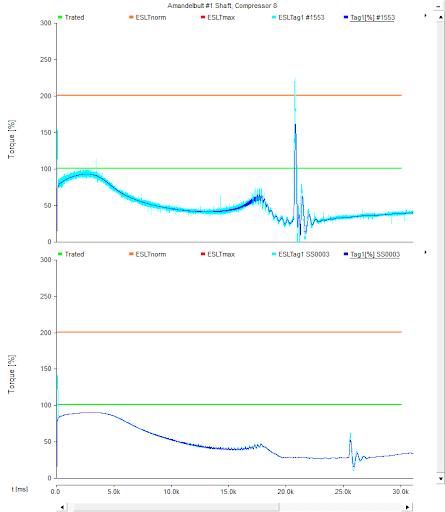

- The airgap torque spike measured when the shorting contactor closes reduced from 161% prior to installation, to 52% after installation of the LRS. Similarly, the equivalent shock load spike came down from 226% to 64%, which is a significant improvement and well within the allowable design limits.

- The TDR increased from 17:1 which was measured in March 2018 to 72:1.

- The improved starter performance enables a wider temperature range for safe start-up – between 22°C and 47°C.

- Improved start-up torque control and less boiling at the end of the start-up cycle

- The LRS start-up performance is also monitored during each start-up which enable timeous problem identification before it results in costly breakdowns and repairs. .

- The mines appointed project manager Alan Northcote commented. “The No 8 compressor was the mines worst performing asset and is now the best performing asset’.

Torque graphs before and after: