Problem

The Barrick Loulo Mine in Mali experienced a large number of failures on their Mill gearboxes as a result of high starting torque spikes.

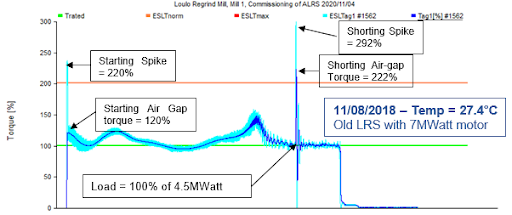

The Starting Torques were more than the maximum allowable limit of 120%. The torque rise in the Critical Area were dangerously high and the Shorting Torque Spikes were more than the maximum allowable limit of 200%.

This resulted in yearly gearboxes replacements on the primary and secondary Mills at a great cost.

INTERVENTION

SDG replaced the existing LRSs with three high turndown ratio ALRSs, fitted with heaters, coolers and integrated Condition Monitoring, Protection and Control systems.

Project outcome

- No gearboxes have failed since the ALRSs have been installed.

- Starting torque spikes are kept within acceptable limits.

- The mills are started at lower torques (near 100% rate torque) without stalling.

- The startup torque is controlled by controlling the electrolyte temperature.

- The number of allowable starts per hour have been increased.

- Barrick also placed an order to replace two of their Tongon mine’s LRSs with ALRSs