Question: The LRS installed on a 1MW crusher is experiencing trips. What about a soft starter solution?

According to our understanding a soft starter will not be able to supply the required starting torque for this application?

What are the preferred starting methods for MV slip ring motors sized at about 1MW?

Answer: With a moving electrode type LRS, the starting torque can be very well controlled if the LRS is tuned correctly, the water temperature is well controlled and the electrodes are in a good condition.

Therefore any start-up torque may be chosen, as hard or soft as needed. No other soft start solution is necessary.

Other liquid starters are in use around the 1MW level, eg. Vapourmatic starters, that do not have a moving electrodes but rather several fixed tanks. With these starters, the torque cannot be well controlled, in which case an upgrade to moving electrode LRS may be in order.

If you already have a moving electrode LRS (like the EPM1), we can test the LRS and tune the starter electrolyte solution to give the required start-up torque.

Crushers are typically started very often, leading to overheating of the water and subsequent tripping. If this is the case we can install our standard air-blast cooler to control temperature at a set-point.

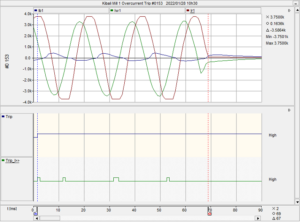

If you need to find the root cause of the trips, we can install a portable (or permanent) recorder to monitor start-ups remotely for a period of time, in order to recommend the best solution.

Some factors that can influence a start-up of a crusher are:

- The time it takes to complete the start-up cycle: if it is an EPM variable resistor starter, the cycle time might be too long. Crushers have less inertia and should start faster compared to mills and fans. Speed is also needed to give momentum for the crushing, when start with ore in the crusher.

- Starting under load can cause tripping (based on the resistance/conductivity of the electrolyte solution). The type of ore can be the determining factor for tripping. If the ore is too hard (like chrome ore or magnetite), starting under load might not be possible, but with copper, gold and platinum it can be done. From experience we found that the starting torque need to be in the order of 180 – 200% of rated torque, when starting under load.