INTRODUCTION

A wound-rotor motor, also known as slip ring-rotor motor, is a type of induction motor where the rotor windings are connected through slip rings to external resistance. Adjusting the resistance allows control of the speed/torque characteristic of the motor. Wound-rotor motors can be started with low inrush current, by inserting high resistance into the rotor circuit; as the motor accelerates, the resistance can be decreased.

In wound rotor induction motors the rotor coils are connected via slip-rings on the motor shaft in series with external variable resistors. The external resistors used are liquid resistors.

Two electrodes per rotor phase are placed in a conductive liquid bath and moved closer together during start-up. This cause the rotor current to increase. When the rotor current increase the motor produce more torque and speeds up.

APPLICATIONS OF LIQUID RESISTANCE STATORS (LRSs)

Wound rotor induction motors(WRIM) are used in applications where large starting torque are required, for example in grinding mills, large fans and pumps.

IMPORTANT CHARACTERISTICS OF LIQUID RESISTANCE STARTOR. (LRS)

As the electrodes in a LRS are moved closer to each other the resistance between the electrodes is reduced. As the electrodes is moved to the minimum distance position a short is placed across the resistors to reduce the resistance to zero and supply maximum current and torque to the motor.

Important characteristics of Liquid Resistance Starters are the:

Turn-down ratio.

This is the ratio of the maximum resistance of the LRS to the minimum resistance before the short is placed in position. The short is placed in position with a shorting contractor. A good turn-down ratio will limit the starting torque of the motor to an acceptable value.

A good turn-down ratio for a 5mW LRS is a 100 or more.

The starting torque of a Wound Rotor Induction motor should not be more than 120% of the rated torque.

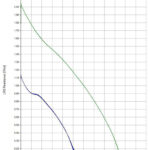

LRS working temperature range

The working temperature range of an LRS is the electrolyte temperature range over which the LRS can be operated without introducing too high starting and shorting spikes on the motor drive train.

The LRS working temperature range is dependent on:

i) the LRS turn-down ratio.

ii) the LRS electrolyte mixture strength.

Iii) and the condition the LRS electrodes.

TESTING THE PERFORMANCE OF AN LRS

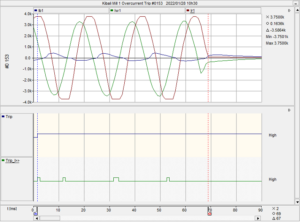

The testing method that I would advocate is a startup torque test.

To do a startup torque test, current transformers (CTs) needs to be installed on the LRS cables to the LRS Electrodes.

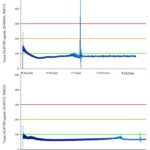

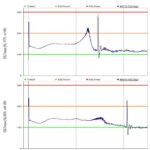

The start-up LRS currents traces can the be captured with a suitable oscilloscope or recorder and analyzed.

It is important to note that the current is directly equivalent to the motor torque produced. 100% rated motor rotor current is equivalent to 100% torque.

Another important measurement is the LRS electrolyte temperature.

It is also important to be able to measure the LRS Electrolyte conductivity.

It might be necessary to dilute or increase the electrolyte strength to alter the LRS torque performance.

Click to view